|

|

|

HEI Inclined Plate Clarifiers Use Gravity & Innovative Engineering.

HEI Inclined Plate Clarifiers Use Gravity & Innovative Engineering.

A gravity clarifier is the most economical method

of removing solids from liquid because natural gravity is the source of

energy and it is free. A clarifier simply provides a non-turbulent zone

where heavier than liquid solids, suspended by turbulence, are given

sufficient time to settle to a quiescent surface. The HEI inclined

plate clarifiers are compact units with multiple layers of settling

area utilizing less than 25% of the floor space required by

conventional clarifiers.

Principle of Horizontal Clarifier |

A particle carried forward by the velocity of the

liquid flow must settle at a rate that allows it to reach the bottom

before passing through the clarifier. Thus, particles beginning at a

point "a" must traverse some route lying between ab and ab' in order to

avoid being carried over the outlet.

If V is the horizontal velocity of the liquid, S

the solids particle vertical settling velocity, L the length of the

settling device, and D its depth, then particles entering at point A

will settle to the bottom of the device only if V does not exceed:

S(L/D)

Since Vmax / S = L / D then, Vmax = S (L / D)

Therefore, the velocity at which a horizontal

clarifying device may be operated successfully is directly proportional

to its length and inversely proportional to its depth.

This

analysis applies to multiple horizontal plate units also. The spacing

between plates is usually a few inches as opposed to a depth of several

feet in a horizontal tank; therefore, "settling-out" times are

dramatically reduced. The flow must be non-turbulent to prevent settled

solids from being reentrained within the moving liquid. Small plate

spacing and a large surface area permits laminar flow at higher

velocities than large horizontal tanks would allow.

This

analysis applies to multiple horizontal plate units also. The spacing

between plates is usually a few inches as opposed to a depth of several

feet in a horizontal tank; therefore, "settling-out" times are

dramatically reduced. The flow must be non-turbulent to prevent settled

solids from being reentrained within the moving liquid. Small plate

spacing and a large surface area permits laminar flow at higher

velocities than large horizontal tanks would allow.Horizontal clarifying devices become self-flushing

if they are inclined at an angle which exceeds the angle of repose of

the settled solids. In such cases, flow enters the lower end of the

device where settling particles move to the floor eventually sliding

back out the entrance. Clear effluent leaves the top of the device.

However, when the device is inclined, the furthest

settling particles no longer fall through distance D but some longer

distance D'. This new longer settling distance D' is related to D by

the relation: D = D' cos Ø.

Theta "Ø" is the angle, the device is inclined to

the horizontal plane. Thus settling distance is increased by the

factor: 1/cos Ø In the case where Ø = 60º, 1/cos Ø = 2.

The maxi mum settling distance is twice the

distance between the plates. It is apparent then that the lower the

angle of inclination, the smaller the settling distance. However, the

angle of inclination must exceed the angle of repose of the solids to

be separated. The previous equation may be modified to express the

cosine of an inclined plate clarifying system as:

Vmax = L / (D / cosØ) (s) = L·cosØ / D (s)

Inclined Plate Clarifier |

A reduction of the required floor space is

acquired by diminishing the separation between the horizontal plates to

a few inches and stacking the settling surfaces. Inclining the plates

to provide self flushing, 45º for heavy particles and 60º for light

particles, reduces the available horizontal projected area (effective

settling area) by a factor equivalent to the cosine of the angle. The

surface area diagram (below) graphically compares the floor space

requirements of an HEI inclined plate clarifier with the equivalent

horizontal projected settling area.

Settling Rate |

The settling rate for a specific solids should be

determined by standard laboratory tests. Light particles, such as metal

hydroxides, usually require a design parameter of 0.25 gallons per

minute per square foot of horizontal projected area. These low density

solids require the inclined plates to be set at a 60º angle to induce

the particles to slide down the plate. Heavier particles (such as sand

that easily flow) will readily slide from plates set at a 45º angle.

Maximum flow rate of an inclined plate clarifier

is based on the flow rate per unit of a horizontally projected surface

area. Retention time in the clarifier is not a design criteria.

However, attaining optimum performance requires the prudent design to

recognize several additional, very important factors.

Inlet Plenum |

An inlet plenum must be provided to uniformly

distribute the influent to the inclined plate compartments. Laminar

flow must be established as the flow enters the plate area. The

hydraulic momentum of the incoming liquid must be dissipated to prevent

channeling. The HEI design does not use orifices which may clog with

heavy suspended solids.

Outlet Area |

The

outlet area must be designed to force uniform flow from all plate

compartments and also over the entire width of the plates. For example,

wide plates (4 foot and over) with side outlets do not utilize the

center section and must be proportionately decreased. A poorly designed

outlet can result in one 50-60% plate utilization. The HEI clarifier

utilizes an orifice type weir with orifices placed on each side of the

plate to force uniform flow from each compartment.

The

outlet area must be designed to force uniform flow from all plate

compartments and also over the entire width of the plates. For example,

wide plates (4 foot and over) with side outlets do not utilize the

center section and must be proportionately decreased. A poorly designed

outlet can result in one 50-60% plate utilization. The HEI clarifier

utilizes an orifice type weir with orifices placed on each side of the

plate to force uniform flow from each compartment.

Equalization Compartment |

The HEI inclined plate clarifier provides

equalized flow between two or more plate packs. After installation,

clarifiers will often settle which creates channeling and turbulence

through one of the plate packs. A prudent design prohibits channeling.

Solids Removal |

|

Solids sliding off the plates must be provided

with a sufficiently large compartment to insure adequate capacity for

the accumulated solids. Turbulence and channeling are avoided by

continuously removing the solids which will disrupt the flow pattern if

allowed to build up and contact the inclined plate.

There

are essentially only two designs of sludge storage compartments in

general use. The conventional design is an inverted cone or pyramid

with angles to match the expected angle of repose of the solids to be

collected. There

are essentially only two designs of sludge storage compartments in

general use. The conventional design is an inverted cone or pyramid

with angles to match the expected angle of repose of the solids to be

collected.Due to the hydrostatic head present before and

during sludge removal, two adverse conditions tend to be created. The

sludge which accumulates between draw downs will compact, changing its

angle of repose. With the draw off pipe open the hydrostatic head will

cause the more fluid supernatent to create a channel (rat hole) from

the top sludge layer to the outlet. The result is too much liquid and

not enough sludge removed.

The preferred design is a compartment with almost

a flat bottom and a top driven motorized rake which will break up

compacted sludge and direct the sludge to the center discharge point

preventing the "rat hole" phenomenon. This design also allows for the

maximum amount of sludge storage below the plates for a given height

(three time as much as a cone bottom design). |

HEI Inclined Plate Clarifier with Motorized Sludge Rake |

Sludge Thickening |

For

most applications there is insufficient volume below the inclined

plates to provide adequate storage time to attain sludge thickening or

compaction. A secondary tank is required to provide sufficient storage

time to accumulate and thicken the collected solids. Laboratory studies

must be performed on each sludge to determine thickening rate. Usually

sludges must be retained in non-turbulent condition for 4-24 hours to

reach an optimum concentration. A typical well-flocculated clarifier

influent may contain 300-500 ppm suspended solids. The solids will

settle to a volume of approximately 10% of the initial volume

(0.3-0.5%). Hence, a 10% underflow is required to remove the

accumulated solids. The sludge accumulator or sludge thickener must

have the capacity to store the accumulated solids for at least 24

hours. The filter press or other compaction device must be sufficiently

large to continuously compact the collected solids. Contact your HEI

technical representative to assist you in the sizing of your liquid

solids separation and solids compaction system.

For

most applications there is insufficient volume below the inclined

plates to provide adequate storage time to attain sludge thickening or

compaction. A secondary tank is required to provide sufficient storage

time to accumulate and thicken the collected solids. Laboratory studies

must be performed on each sludge to determine thickening rate. Usually

sludges must be retained in non-turbulent condition for 4-24 hours to

reach an optimum concentration. A typical well-flocculated clarifier

influent may contain 300-500 ppm suspended solids. The solids will

settle to a volume of approximately 10% of the initial volume

(0.3-0.5%). Hence, a 10% underflow is required to remove the

accumulated solids. The sludge accumulator or sludge thickener must

have the capacity to store the accumulated solids for at least 24

hours. The filter press or other compaction device must be sufficiently

large to continuously compact the collected solids. Contact your HEI

technical representative to assist you in the sizing of your liquid

solids separation and solids compaction system.

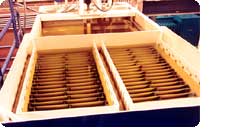

Construction |

HEI inclined plate clarifiers are constructed of

1/4" ASTM A36 structural carbon steel. The inclined plates are fiber

reinforced plastic with spacers and brackets fabricated of 304

stainless steel and polyvinyl chloride plastic. Units will be

fabricated entirely of stainless steel on request. All carbon steel

surfaces are media blasted to SSPC SP-6 finish and coated on the

interior with high build polyester epoxy and the exterior with acid

resistant epoxy. The units will be coated with FRP on request.

Manufacturing Specifications |

|

|

Optional Equipment |

-

Flash mix & flocculate sections with mixers

-

Acid resistant FRP coating on interior and/or exterior

-

All stainless steel construction

-

Pumping systems

-

Automatic sludge removal system

-

Oil skimmers

-

Covers

-

Ladders and platforms

-

Seismic zone certification

Installed Dimensions HEI Inclined Plate Clarifier |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

NOTES:

-

HEI Model No. (110/60/SA) typically indicates: 110 sq. ft. horizontal projected area. 60 indicates the angle of inclination of the plates, "m" indicates motorized sludge rake, "s" indicates sloped bottom, A indicates the length of the settling plate, A is 30" long, B is 60" long, C is 120" long.

-

Flash mix and flocculation sections for 2,000 sq. ft. and greater size clarifiers are shipped separately.

-

Clarifiers supplied with 45° inclined plates will have 40% more horizontal projected area for the equivalent outside dimensions.

-

Dimensions given are approximate.

-

HEI will custom fabricate clarifiers to accommodate reduced floor space or ceiling heights.

-

Dimensions of units having 1,000 sq. ft. or less include flash floc sections.