|

|

|

Tri-Packs ® energy-conserving tower packing media is the ultimate in random dump tower packing.

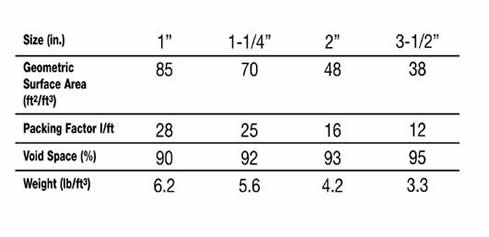

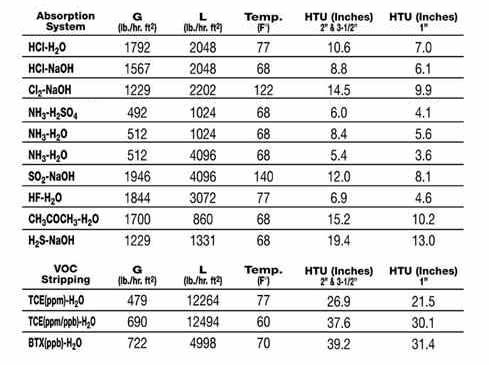

Tri-Packs tower packing provides maximum surface contact between the gas and the scrubbing liquid by facilitating continuous formation of droplets throughout the packed bed. This results in high scrubbing efficiency, and minimizes total packing depth required. The distinctive shaping of ribs, struts and drip rods gives Tri-Packs tower packing media superior wetting characteristics, and the ability to maintain uniform liquid distribution throughout the bed. Tri-Packs Tower Packing also prevent clogging, because there are no flat surfaces or minute openings to harbor particulate. Tri-Packs tower packing eliminates puddling too, because it's free of corners and valleys, and minimizes wasteful liquid flow down the wall surfaces. Tri-Packs further prevents dry spots and compression interlock, two phenomena common to traditional packing media. Both conditions cause liquid and air channeling and decrease media efficiency. Note to specifiers: Surface area alone does not guarantee performance. Excess surface area can impede gas/liquid contact and create higher pressure drops, thus increasing horsepower requirements and operating expense. Tri-Packs tower packing provides the optimum surface-to-open-area ratio for achieving best mass transfer efficiency and lowest operating costs. It is the industry standard for random dump tower packing media. Tri-Packs Tower Packing is available in four sizes in a variety of injection-molded resins including polypropylene, KYNAR ®, and glass-filled polypropylene. Physical Properties of Tri-Packs Tower Packing Mass Transfer Data of Tri-Packs

|

|