|

|

|

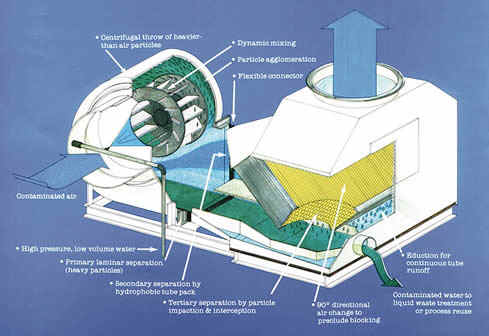

Fan / Separator scrubs corrosive metal finishing fumes at 1/10th the water of other wet scrubbers.

Tri-Mer’s Fan / Separator is an all-mechanical system that operates with 20% less brake horsepower. High efficiencies are possible due to the system's unique use of the fan as a centrifuge in the scrubbing process. Fan velocity is precisely controlled so that air crossing the rigid packed media stays within design parameters. The system is positively pressured, working the reverse of conventional “negative air” scrubbers. Thus, air is pushed, rather than pulled, through the system. 55% of system performance results from contact between the contaminant-laden air and the rigid tube packing; 45% is from the centrifugal action of the fan wheel. The unit is extremely effective in eliminating corrosive contaminants, with a resulting low humidity stack. Total energy consumption is generally 15 to 20% less than comparable wet scrubbers with a negative pressure design. The Fan/Separator is widely used for fumes from sulfuric acid, pickling, metal plating and battery charging operations. Because the moisture eliminator is on the downstream side of the fan, scrubbed air can sometimes be returned to the plant, saving HVAC costs. The Fan / Separator was engineered for simple installation and start-up, so start-up costs are low. Fan and Separator are mated specifically to each other. Materials of construction include polypropylene, PVC, fiberglass-overlayed PVC and stainless steels. Tri-Mer has supplied Boeing, Hamilton Sundstrand, GE, GM, Texas Instruments, Motorola, TABC, Criterion Catalyst, and hundreds of other manufacturers and job shops with emissions control systems that operate at 95-99% + efficiency, even under highly variable loadings. To demonstrate the effectiveness of the Fan / Separator in your facility, Tri-Mer offers a Pilot Plant Program. |

|